VLE Thermodynamic Consistency: Pure Component Consistency Test background

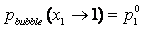

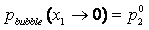

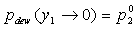

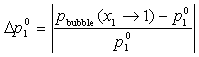

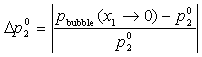

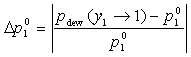

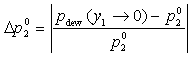

Pure Component Consistency Test. In addition to the requirements related to the Gibbs-Duhem equation described, consistency is checked between the "end-points" of the VLE curve (i.e., mole fraction composition approaching 0 or 1) and the pure-component vapor pressures. The check is made for both the liquid-phase compositions x and gas-phase compositions y.

and

and

and

and

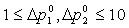

If the data set type is T-p-x-y, these equations are equivalent. For T-p-x data, the first is used, and for T-p-y data, the second equation is used. If no experimental values are reported at x1 = 0 or x1 = 1 in the VLE set, the values of Δ and Δ

and Δ can be calculated with extrapolated vapor pressures derived with the 3-parameter NRTL model. The vapor pressures and three NRTL parameters (five parameters in total) are fitted to experimental VLE values with the following conditions; (1) the data set is isothermal, (2) the minimum number of experimental values is 8, (3) there is, at least, one experimental value in the composition range x1 < 0.2 to allow estimation of the vapor pressure for component 2, (4) there is a minimum of one value in the composition range from x1 > 0.8 to allow estimation of the vapor pressure for component 1. If the data set is isobaric or any of the four conditions are not met, the values of Δ

can be calculated with extrapolated vapor pressures derived with the 3-parameter NRTL model. The vapor pressures and three NRTL parameters (five parameters in total) are fitted to experimental VLE values with the following conditions; (1) the data set is isothermal, (2) the minimum number of experimental values is 8, (3) there is, at least, one experimental value in the composition range x1 < 0.2 to allow estimation of the vapor pressure for component 2, (4) there is a minimum of one value in the composition range from x1 > 0.8 to allow estimation of the vapor pressure for component 1. If the data set is isobaric or any of the four conditions are not met, the values of Δ and Δ

and Δ are replaced by the average deviation in bubble or dew pressure calculated with the 3-parameter NRTL model fit based on pure component vapor pressures.

are replaced by the average deviation in bubble or dew pressure calculated with the 3-parameter NRTL model fit based on pure component vapor pressures.

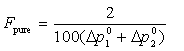

Unlike the four consistency tests based on the Gibbs-Duhem equation, this test can be performed for T-p-x or T-p-y data sets. The quality factor associated with the Pure Component Consistency Test is defined as:

, with limits:

, with limits:

, with limits:

, with limits:

In this study, the values of Δ and Δ

and Δ have lower limits of 1. If the vapor pressure agrees within 1% of po for both components, the factor Fpure is 1. If the vapor-pressure inconsistency is larger, the factor is smaller with a lower limit of 0.1.

have lower limits of 1. If the vapor pressure agrees within 1% of po for both components, the factor Fpure is 1. If the vapor-pressure inconsistency is larger, the factor is smaller with a lower limit of 0.1.

, with limits:

, with limits: